Nov 25, 2010

Nov 17, 2010

Nov 14, 2010

Fighter AirCraft Wallpapers(HD) - F-15 EAGLE

High Definition(HD) Wallpapers -

F-15 EAGLE fighter aircraft...

F15e eagle aircraft

F15 eagle from nellis air force base

F15 eagle moves into position

F15 eagle receives fuel from KC135 Stratotanker

F15e strike eagle dual role fighter

F15e strike eagle pops flares

F15e strike eagles & B2 Spirit Bomber

Nov 12, 2010

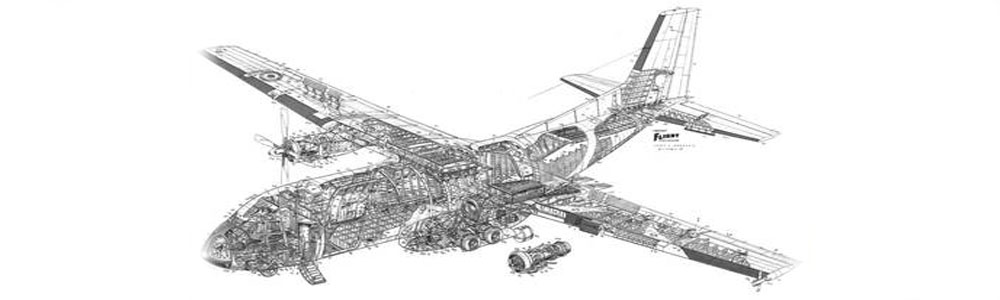

DHC-4 CARIBOU

DHC-4 CARIBOU - De Havilland Canada 1958

- MODEL -DHC-4A Caribou

- CREW -2

- PASSENGERS -32

- ENGINE -2 x Pratt & Whitney R-2000-7M Twin Wasp, 1081kW

- Take-off weight -12927 kg

- Empty weight -8283 kg

- Wingspan -29.15 m

- Length -22.12 m

- Height -9.68 m

- Wing area -84.72 m2

- Max. speed -348 km/h

- Cruise speed -293 km/h

- Ceiling -7560 m

- Range w/max.payload -389 km

The decision to build the de Havilland Canada DHC-4 Caribou was taken in 1956, the object being to develop an aircraft combining the load-carrying capability of the Douglas DC-3 with the STOL performance of the Beaver and Otter. The Canadian army placed an order for two and the US Army followed with five, the US Secretary of Defense waiving a restriction which limited the US Army to fixed-wing aircraft with an empty weight less than 2268kg.

The prototype flew in July 1958, its high wing having a characteristic centre-section with marked anhedral. The rear door was designed as a ramp for items weighing up to 3048kg. In the trooping role up to 32 soldiers could be carried. The Caribou served with the RCAF as the CC-108 and with the US Army as the AC-1 (1962 designation CV-2A). As a result of its evaluation of the first five aircraft the US Army adopted the Caribou as standard equipment and placed orders for 159.

The second batch of aircraft was designated CV-2B. Following tension on the border between China and India, the US Army handed over two Caribous to the Indian Air Force in early 1963. In January 1967 the 134 Caribous still in service with the US Army were transferred to US Air Force charge as C-7A and C-7B transports. The aircraft was a general sales success and examples flew not only with air forces throughout the world, but also with civil operators. In Canadian service the Caribou was replaced by the DHC-5 Buffalo and surplus examples were sold to a number of nations including Colombia, Oman and Tanzania. Many of the Canadian aircraft had been loaned to the United Nations, seeing extensive international service. Production ended in 1973. The DHC-4A model supplanted the DHC-4 on the production line from aircraft no. 24: the two models are very similar apart from the later model's increase in weight, maximum take-off weight of the DHC-4 being 11793kg. Total production was 307.

DHC-4 Caribou Video

Australian International Airshow 2011

1 March 2011 00:00 to 6 March 2011 00:00

The Royal Australian Air Force (RAAF) is planning to make the 2011 Australian International Air Show a centrepiece of RAAF’s 90th anniversary activities, Chief of Air Force, Air Marshal Mark Binskin announced today.

The Air Show at Avalon next March will be one of the largest and most comprehensive air shows ever conducted in the Southern Hemisphere.

“The air show will coincide with RAAF’s 90th Anniversary. So the 90th will be a key theme for this world class event which is run by Air Shows Down Under,” Air Marshal Binskin said.

“This will be a great opportunity for the public to get a close look at Air Force’s current high-tech fighter and strike capabilities, including the potent F/A-18F Super Hornet and the Wedgetail airborne early warning and control aircraft, both of which came into RAAF operational service this year.”

The air show will be a major opportunity to highlight RAAF’s future, in particular our transition to the cutting-edge Joint Strike Fighter,” Air Marshal Binskin said.

“The Avalon air show and associated conferences will also focus on unmanned aircraft. Air Force’s Heron is already providing crucial support to operations in Afghanistan, and remotely piloted aircraft will be a key feature of our future capability.”

“We anticipate nearly all of Air Force’s aircraft types will be represented at Avalon next year, along with Navy and Army aviation assets. Dozens of Australian Defence Force aircraft will participate. We’re also planning major displays of the ADF’s ground-based equipment and capabilities.”

“The Australian International Air Show is a key opportunity for Defence to engage our industry partners. The air show and conferences will also draw senior military personnel from the Asia Pacific region and across the world. This makes it an ideal forum to meet and exchange ideas with our international military counterparts,” Air Marshal Binksin said.

More about Australian International Airshow 2011

The Royal Australian Air Force (RAAF) is planning to make the 2011 Australian International Air Show a centrepiece of RAAF’s 90th anniversary activities, Chief of Air Force, Air Marshal Mark Binskin announced today.

The Air Show at Avalon next March will be one of the largest and most comprehensive air shows ever conducted in the Southern Hemisphere.

“The air show will coincide with RAAF’s 90th Anniversary. So the 90th will be a key theme for this world class event which is run by Air Shows Down Under,” Air Marshal Binskin said.

“This will be a great opportunity for the public to get a close look at Air Force’s current high-tech fighter and strike capabilities, including the potent F/A-18F Super Hornet and the Wedgetail airborne early warning and control aircraft, both of which came into RAAF operational service this year.”

The air show will be a major opportunity to highlight RAAF’s future, in particular our transition to the cutting-edge Joint Strike Fighter,” Air Marshal Binskin said.

“The Avalon air show and associated conferences will also focus on unmanned aircraft. Air Force’s Heron is already providing crucial support to operations in Afghanistan, and remotely piloted aircraft will be a key feature of our future capability.”

“We anticipate nearly all of Air Force’s aircraft types will be represented at Avalon next year, along with Navy and Army aviation assets. Dozens of Australian Defence Force aircraft will participate. We’re also planning major displays of the ADF’s ground-based equipment and capabilities.”

“The Australian International Air Show is a key opportunity for Defence to engage our industry partners. The air show and conferences will also draw senior military personnel from the Asia Pacific region and across the world. This makes it an ideal forum to meet and exchange ideas with our international military counterparts,” Air Marshal Binksin said.

More about Australian International Airshow 2011

Apr 9, 2010

Boeing 787 (Dreamliner) - 2010/USA

The 787 "Dreamliner" represents Boeing's latest foray into the world of commercial passenger air travel. To this point, the project represents an advanced, ambitious project which could sink or swim the aircraft firm which already suffers from a down economy and drop in air travel in general. Should it succeed as planned, the 787 sets the stage to become the top-performing jet airliner that Boeing has ever produced. The program was launched back in 2004 though first flight was not achieved until late 2009, some two years late. The 787 was unveiled in a "roll-out" ceremony on July 8th, 2007. Before it had even flown, the 787 became the fastest-selling wide-body class airliner in history, perhaps a sign of better things to come for the Boeing Company. The Dreamliner will wield parts, materials and entire components through a multitude of national and international companies across the United States, Russia, France, the United Kingdom, Japan, India and Italy among others.

First Operators

As of this writing, the Boeing 787 Dreamliner has not entered operational service with any one airliner firm. All Nippon Airways Company, Ltd of Japan is slated to be the first commercial operator of the Boeing product. These 787s are expected to hit the airways in the latter portion of 2010 if the program continues on track.

Some 54 airliner firms are expected to begin 787 Dreamliner operations between late 2010 through 2017. On paper, the two largest expected customers will be ILFC (International Lease Finance Corporation) of the United States with 67 examples and Al Nippon of Japan with 55 examples. Some top names to utilize the Dreamliner will include Aeroflot, AeroMexico, Air Berlin, Air Canada, Air China, Air India, Kuwait Airways, British Airways, Continental Airlines, Delta Airlines, Japan Airlines, Korean Air, Qantas and Virgin Atlantic Airways. Each operator will make their own respective selection as to engine brands (General Electric or Rolls Royce) and all of these are slated to use the 787-8 and 787-9 production model types.

Boeing 787 Dreamliner Walk-Around

To the casual observer, the 787 does not offer much in the way of changes, at least from an external perspective. The design is, in fact, quite conventional in appearance despite some early Dreamliner design interpretations featuring a fashionable and futuristic airframe. The fuselage is tubular with the flightdeck situated at the extreme forward of the design. The conical nose is noticeably short and the cockpit sports four large window panels. The two center windscreen panels are afforded individual windshield wipers. There are four crew/passenger access doors to either fuselage side. The first set is immediately aft of the cockpit with the second set just a ways down the fuselage ahead of each wingroot. The third, is set just aft of the main wing assemblies with the fourth set ahead of the empennage. The wings themselves are low-mounted in typical commercial airliner fashion and sport noticeable dihedral. Wing sweep (approximately 32.2 degrees) is noticeably excessive along the leading edge and less so along the trailing edge. The empennage is also conventional and dominated by the tall shark-like vertical fin. Horizontal planes extend out of each aft fuselage side and showcase their own dihedral. The fuselage tapers off into a sharp cone past the tail. The undercarriage is made up of a two-wheeled nose landing gear leg and a pair of 4-wheeled main landing gears. The main legs are fitted under each wingroot with the nose leg fitted under and aft of the cockpit floor.

Internally, the 787 makes use of composites, aluminum, titanium and steel, producing a light-weight airframe in the process (theoretically improving range). The fuselage will rely heavily on composite construction and make the 787 the first commercial passenger airliner to do so. The use of composites has come under some scrutiny from outside parties when relating its use with lighting strikes, visible fatigue markers, crash survivability and moisture absorbance. Boeing, of course, counters these fears with the data they have available.

The 787 Cockpit

The 787 Dreamliner flightdeck naturally sports state-of-the-art equipment. The instrument panel is dominated by a set of four large liquid-crystal customizable multi-function displays (MFDs) similar to those found on military aircraft for decades. Engine controls are located between the pilot and copilot along an easily accessible central console. Each pilot position is redundant to an extent and feature a traditional yoke control column (as opposed to the side stick controls found in the Airbus 380 and in military aircraft). Heads-Up Displays (HUDs) are fixed to the cockpit ceiling directly ahead of each pilot's sight line and supply pertinent in-flight information on-the-fly and without the need for the pilots to take their eyes off of the air ahead. The curved cockpit ceiling also contains easily accessible control systems.

Dreamliner Orders

As of this writing, some 851 Dreamliners are on order and most of these are of the 787-8 type (656 examples) whilst the rest are of the 787-9 type (195 examples). No orders for the 787-3 have been placed as of yet. Orders began as early as 2004 with 56 being placed. 2005 saw 235 examples placed on order while 2006 netted a further 157. A total of 369 orders were placed in 2007 while 93 came onboard in 2008. 2009 saw 59 examples ordered.

Production

Taking a page out of those expensive and complicated military aircraft in today's skies, Boeing is utilizing subcontractors to produce individual sections and components of the Dreamliner with final production being handled by Boeing. As of this writing, only two 787s have been completed with first flight achieved on December 15th, 2009. The 787-3 is expected to cost between $150 - $155.5 million USD per example while the 787-8 will range in the $161 - $171.5 realm. The 787-9 is priced out between $194 - 205.5 million.

787 Variants - the 787-3, 787-8, 787-9 and 787-10

The 787-3 is the short-range model of the 787 Dreamliner family. The 787-3 features a standard operating crew of two personnel made up of the pilot and copilot. Seating is expected to be between 290 and 330 passengers depending on the cabin seat arrangements. Length is listed at 186 feet with a wingspan of 170 feet and a height of 55 feet, 6 inches. The fuselage measures in at 19 feet, 5 inches high with a width of 18 feet, 11 inches. The cabin itself measures in at 18 feet across. These fuselage measurements are the same across the 787-3, 787-8 and the 787-9 model types. Empty weight for the 787-3 is listed at 223,000lbs while a maximum take-off weight (MTOW) of 375,000 is reported. Cruising speed will be approximately 561 miles per hour while a maximum speed of 587 miles per hour is possible. Range will fall between 2,880 and 3,510 miles. Service ceiling is 43,000 feet across all three Dreamliner models. The 787-3 is intended to replace the 757-300 and 767-200 Boeing products as well as threaten the future of the categorically similar Airbus A300 and A310 in use. As of this writing, no 787-3s have been ordered and no date is set for its availability.

Despite the number designations, the 787-8 actually represents the "base" 787 Dreamliner product. The 787-8 will feature seating between 210 and 250 passengers depending on the arrangement. Wingspan is a wider 197 feet, 3 inch design featuring the same 32.2 degree sweepback. Height, fuselage and cabin measurements all mimic the 787-3 model. Empty weight is listed at 242,000lbs and MTOW is 502,500lbs. Speed specifications are all equal to the 787-3 though range is now increased in an impressive 8,000 to 9,440 mile distance. The 787-8 should eventually replace the 767-200ER and 767-300ER models in the Boeing product line. Operations are expected to begin sometime in late 2010.

The 787-9 is the "stretch" product of the 787 Dreamliner family line, essentially a long-fuselage Dreamliner, featuring room for 250 to 290 passengers. Length is reported at 206 feet while sharing the same 197 foot, 3 inch wingspan of the 787-8 model. Height, fuselage and cabin measurements are equal to the 787-3 and 787-8 models though internal cargo capacity is greater than the two. Empty weight is 254,000lbs with a MTOW of 547,000lbs. Speed measurements are equal across all three models. Range of the 787-9 is now increased out to 9,210 to 9,780 miles in its defined long-range role. The 787-9 is expected to replace the 767-400ER in the Boeing product line and threaten the future use of the Airbus A330 series. Operations are expected to begin sometime in 2013.

The 787-10 is a proposed variant based on the 787-9 to compete directly for customers eyeballing the French Airbus A350-900 series for their passenger transport needs. It represents a stretched fuselage model with seating between 290 and 310 passengers. The added passenger space will decrease the overall operational range and internal cargo capabilities of the base 787-9 design but the move is to feed potential Boeing customers and their respective requirements. Though not officially launched as a product by Boeing, all indications are that the aircraft will be a committed addition to the Dreamliner product line in the near future.

Other Dreamliner variants may include a cargo hauler and military transport/refueler type - though there is no commitment on any of these fronts from both Boeing or the US military. There is a rumor that the 787 could replace the 747-series VC-25 "Air Force One" within time.

787 Dreamliner Engines

Engine choices for the 787 will be the General Electric (GE Aviation) GEnx or the Rolls Royce Trent 1000 series turbofan engines. The choice for Boeing to go with two suppliers is something of a departure from the norm for the company and essentially brought about by customer desires. Thrust output per powerplant model will be as follows (x2 engines) - 53,000lbs (for the 787-3), 64,000lbs (for the 787-8), 71,000lbs (for the 787-9). The engine partners were announced on April 6th, 2004. The GEnx is looking to become the successor to the aging CF6 turbofan series. Engine manufacturer Pratt & Whitney submitted a powerplant proposal but was not selected.

The multiple choice of engine types means that the 787 Dreamliner will promote a "quick-change" powerplant feature designed to accept either engine brand type (GE or Rolls Royce). Boeing targets some 24 hours for the switch to take place, making this a cost-effective and expedient measure for its operators. There is some concern on the part of potential customers that expect the engine switch to take place in the range of fifteen days due to the complex nature of the systems involved when dealing with this process. Boeing is optimistic that it will meet its 24-hour turnaround goal.

Other Items of Note

Boeing wanted the 787 Dreamliner to supply its passengers with in-flight internet access so a network was designed and integrated into the aircraft. However, the network is said to be tied with the aircraft's critical internal systems including flight control and navigation as well as the communications suite. This has raised some alarms with the FAA that passengers may be able to gain access (either forcibly or accidentally) to these sensitive systems in-flight. Boeing has rebutted this concern by explaining the various protective measures in place to keep the passenger network access separate from the actual aircraft network systems. Once thoroughly tested and completed, Boeing will supply its proof to the FAA to solidify the systems safety.

As expected in any aircraft development program, weight has inevitably crept up on the 787 much to the dismay of its potential customers. Added weight in airplane-speak translates to reduced range with the inherently higher fuel consumption involved. Boeing is continuing tests and will use the first six 787 production models to improve the design.

The 787 Dreamliner was formerly known under the designation of "7E7". This changed as of January 28th, 2005.

First Operators

As of this writing, the Boeing 787 Dreamliner has not entered operational service with any one airliner firm. All Nippon Airways Company, Ltd of Japan is slated to be the first commercial operator of the Boeing product. These 787s are expected to hit the airways in the latter portion of 2010 if the program continues on track.

Some 54 airliner firms are expected to begin 787 Dreamliner operations between late 2010 through 2017. On paper, the two largest expected customers will be ILFC (International Lease Finance Corporation) of the United States with 67 examples and Al Nippon of Japan with 55 examples. Some top names to utilize the Dreamliner will include Aeroflot, AeroMexico, Air Berlin, Air Canada, Air China, Air India, Kuwait Airways, British Airways, Continental Airlines, Delta Airlines, Japan Airlines, Korean Air, Qantas and Virgin Atlantic Airways. Each operator will make their own respective selection as to engine brands (General Electric or Rolls Royce) and all of these are slated to use the 787-8 and 787-9 production model types.

Boeing 787 Dreamliner Walk-Around

To the casual observer, the 787 does not offer much in the way of changes, at least from an external perspective. The design is, in fact, quite conventional in appearance despite some early Dreamliner design interpretations featuring a fashionable and futuristic airframe. The fuselage is tubular with the flightdeck situated at the extreme forward of the design. The conical nose is noticeably short and the cockpit sports four large window panels. The two center windscreen panels are afforded individual windshield wipers. There are four crew/passenger access doors to either fuselage side. The first set is immediately aft of the cockpit with the second set just a ways down the fuselage ahead of each wingroot. The third, is set just aft of the main wing assemblies with the fourth set ahead of the empennage. The wings themselves are low-mounted in typical commercial airliner fashion and sport noticeable dihedral. Wing sweep (approximately 32.2 degrees) is noticeably excessive along the leading edge and less so along the trailing edge. The empennage is also conventional and dominated by the tall shark-like vertical fin. Horizontal planes extend out of each aft fuselage side and showcase their own dihedral. The fuselage tapers off into a sharp cone past the tail. The undercarriage is made up of a two-wheeled nose landing gear leg and a pair of 4-wheeled main landing gears. The main legs are fitted under each wingroot with the nose leg fitted under and aft of the cockpit floor.

Internally, the 787 makes use of composites, aluminum, titanium and steel, producing a light-weight airframe in the process (theoretically improving range). The fuselage will rely heavily on composite construction and make the 787 the first commercial passenger airliner to do so. The use of composites has come under some scrutiny from outside parties when relating its use with lighting strikes, visible fatigue markers, crash survivability and moisture absorbance. Boeing, of course, counters these fears with the data they have available.

The 787 Cockpit

The 787 Dreamliner flightdeck naturally sports state-of-the-art equipment. The instrument panel is dominated by a set of four large liquid-crystal customizable multi-function displays (MFDs) similar to those found on military aircraft for decades. Engine controls are located between the pilot and copilot along an easily accessible central console. Each pilot position is redundant to an extent and feature a traditional yoke control column (as opposed to the side stick controls found in the Airbus 380 and in military aircraft). Heads-Up Displays (HUDs) are fixed to the cockpit ceiling directly ahead of each pilot's sight line and supply pertinent in-flight information on-the-fly and without the need for the pilots to take their eyes off of the air ahead. The curved cockpit ceiling also contains easily accessible control systems.

| The Boeing 787 Dreamliner cockpit screams state-of-the-art. |

Dreamliner Orders

As of this writing, some 851 Dreamliners are on order and most of these are of the 787-8 type (656 examples) whilst the rest are of the 787-9 type (195 examples). No orders for the 787-3 have been placed as of yet. Orders began as early as 2004 with 56 being placed. 2005 saw 235 examples placed on order while 2006 netted a further 157. A total of 369 orders were placed in 2007 while 93 came onboard in 2008. 2009 saw 59 examples ordered.

Production

Taking a page out of those expensive and complicated military aircraft in today's skies, Boeing is utilizing subcontractors to produce individual sections and components of the Dreamliner with final production being handled by Boeing. As of this writing, only two 787s have been completed with first flight achieved on December 15th, 2009. The 787-3 is expected to cost between $150 - $155.5 million USD per example while the 787-8 will range in the $161 - $171.5 realm. The 787-9 is priced out between $194 - 205.5 million.

787 Variants - the 787-3, 787-8, 787-9 and 787-10

The 787-3 is the short-range model of the 787 Dreamliner family. The 787-3 features a standard operating crew of two personnel made up of the pilot and copilot. Seating is expected to be between 290 and 330 passengers depending on the cabin seat arrangements. Length is listed at 186 feet with a wingspan of 170 feet and a height of 55 feet, 6 inches. The fuselage measures in at 19 feet, 5 inches high with a width of 18 feet, 11 inches. The cabin itself measures in at 18 feet across. These fuselage measurements are the same across the 787-3, 787-8 and the 787-9 model types. Empty weight for the 787-3 is listed at 223,000lbs while a maximum take-off weight (MTOW) of 375,000 is reported. Cruising speed will be approximately 561 miles per hour while a maximum speed of 587 miles per hour is possible. Range will fall between 2,880 and 3,510 miles. Service ceiling is 43,000 feet across all three Dreamliner models. The 787-3 is intended to replace the 757-300 and 767-200 Boeing products as well as threaten the future of the categorically similar Airbus A300 and A310 in use. As of this writing, no 787-3s have been ordered and no date is set for its availability.

Despite the number designations, the 787-8 actually represents the "base" 787 Dreamliner product. The 787-8 will feature seating between 210 and 250 passengers depending on the arrangement. Wingspan is a wider 197 feet, 3 inch design featuring the same 32.2 degree sweepback. Height, fuselage and cabin measurements all mimic the 787-3 model. Empty weight is listed at 242,000lbs and MTOW is 502,500lbs. Speed specifications are all equal to the 787-3 though range is now increased in an impressive 8,000 to 9,440 mile distance. The 787-8 should eventually replace the 767-200ER and 767-300ER models in the Boeing product line. Operations are expected to begin sometime in late 2010.

The 787-9 is the "stretch" product of the 787 Dreamliner family line, essentially a long-fuselage Dreamliner, featuring room for 250 to 290 passengers. Length is reported at 206 feet while sharing the same 197 foot, 3 inch wingspan of the 787-8 model. Height, fuselage and cabin measurements are equal to the 787-3 and 787-8 models though internal cargo capacity is greater than the two. Empty weight is 254,000lbs with a MTOW of 547,000lbs. Speed measurements are equal across all three models. Range of the 787-9 is now increased out to 9,210 to 9,780 miles in its defined long-range role. The 787-9 is expected to replace the 767-400ER in the Boeing product line and threaten the future use of the Airbus A330 series. Operations are expected to begin sometime in 2013.

The 787-10 is a proposed variant based on the 787-9 to compete directly for customers eyeballing the French Airbus A350-900 series for their passenger transport needs. It represents a stretched fuselage model with seating between 290 and 310 passengers. The added passenger space will decrease the overall operational range and internal cargo capabilities of the base 787-9 design but the move is to feed potential Boeing customers and their respective requirements. Though not officially launched as a product by Boeing, all indications are that the aircraft will be a committed addition to the Dreamliner product line in the near future.

Other Dreamliner variants may include a cargo hauler and military transport/refueler type - though there is no commitment on any of these fronts from both Boeing or the US military. There is a rumor that the 787 could replace the 747-series VC-25 "Air Force One" within time.

787 Dreamliner Engines

Engine choices for the 787 will be the General Electric (GE Aviation) GEnx or the Rolls Royce Trent 1000 series turbofan engines. The choice for Boeing to go with two suppliers is something of a departure from the norm for the company and essentially brought about by customer desires. Thrust output per powerplant model will be as follows (x2 engines) - 53,000lbs (for the 787-3), 64,000lbs (for the 787-8), 71,000lbs (for the 787-9). The engine partners were announced on April 6th, 2004. The GEnx is looking to become the successor to the aging CF6 turbofan series. Engine manufacturer Pratt & Whitney submitted a powerplant proposal but was not selected.

The multiple choice of engine types means that the 787 Dreamliner will promote a "quick-change" powerplant feature designed to accept either engine brand type (GE or Rolls Royce). Boeing targets some 24 hours for the switch to take place, making this a cost-effective and expedient measure for its operators. There is some concern on the part of potential customers that expect the engine switch to take place in the range of fifteen days due to the complex nature of the systems involved when dealing with this process. Boeing is optimistic that it will meet its 24-hour turnaround goal.

Other Items of Note

Boeing wanted the 787 Dreamliner to supply its passengers with in-flight internet access so a network was designed and integrated into the aircraft. However, the network is said to be tied with the aircraft's critical internal systems including flight control and navigation as well as the communications suite. This has raised some alarms with the FAA that passengers may be able to gain access (either forcibly or accidentally) to these sensitive systems in-flight. Boeing has rebutted this concern by explaining the various protective measures in place to keep the passenger network access separate from the actual aircraft network systems. Once thoroughly tested and completed, Boeing will supply its proof to the FAA to solidify the systems safety.

As expected in any aircraft development program, weight has inevitably crept up on the 787 much to the dismay of its potential customers. Added weight in airplane-speak translates to reduced range with the inherently higher fuel consumption involved. Boeing is continuing tests and will use the first six 787 production models to improve the design.

The 787 Dreamliner was formerly known under the designation of "7E7". This changed as of January 28th, 2005.

Top Ten Fighter Planes - Rank 6 to 10

Rank 6 – F 86 Sabre Year 1949

The F86 was the final production model of a North American Aviation design for a swept-wing day fighter which could also double as a dive-bomber or escort fighter. The F-86 was built in large numbers by the US and saw extensive action in the Korean War, where it was pitted against the slightly superior MiG-15.The F-86 started out life as when two prototype XP-86s were contracted in late 1944, but large scale production did not begin until after WWII.

The first XP-86 prototype flew on 1 October 1947, powered by a 3,750-pound thrust G.E. J35 engine. It was re-engined with a more powerful G.E. J47 turbojet the following spring and was re-designated the YP-86A. With a more powerful engine top speed and ceiling of the new fighter increased significantly and the rate of climb almost doubled.

The F-86A was fitted with a T-4E-1 ejection seat, with a manually jettisoned canopy, plus a self-destruct charge to keep it from falling into enemy hands. The F-86A also had a stores pylon under each wing that could each carry a 782 liter (206.5 US gallons) drop tank or a 450 kilogram (1,000 pound) bomb.

Four zero-length stub rocket launchers could be installed under each wing, with each launcher carrying two 12.7 centimeters (5 inches) “High Velocity Air Rockets (HVARs)” for a total of 16 rockets.

Unfortunately, without the drop tanks, the combat radius fell from about 530 kilometers (330 miles) to 80 kilometers (50 miles). In effect, the only armament of the F-86A was its machine guns, and so in the beginning it was not very useful for close support.

The first production model was initially designated the P-86A, but became the legendary F-86A in June 1948. When the new fighter entered US Air Force service in 1949 it gained the name, the “Sabre”.

Its success led to an extended production run of over 7,800 aircraft between 1946 and 1956, in the

United States, Japan and Italy. The upgraded Canadair Sabre added another 1,815 airframes, while the CAC CA-27 Avon Sabre saw a production run of 112. It was by far the most-produced Western jet fighter, with total production of all variants at 9,860 units.

Specifications

- Engine General Electric J47-GE-17B

- Range 870 km

- Weight 9,136 kg

- Top speed 1,107 km/h

- Dimensions Length: 12.27 m, Height: 4.57 m, Wingspan, 11.92 m

Rank 7 – Harrier Jump Jet (AV-8B Harrier II) Year 1985

British designed military jet aircraft capable of Vertical/Short Takeoff and Landing (V/STOL) via thrust vectoring.The Harrier family is the only truly successful design of this type from the many that arose in the 1960s.

The Harrier family is made up of four main versions:

- Hawker Siddeley Harrier – 1st generation Harrier, also known as the AV-8A Harrier.

- British Aerospace Sea Harrier – Maritime strike/air defense fighter aircraft.

- Boeing/BAE Systems AV-8B Harrier II – 2nd generation Harrier.

- BAE Systems/Boeing Harrier II – British variant of the 2nd generation Harrier.

These were developed directly from the Hawker P.1127 prototype which began after British aircraft manufacturer, Hawker Aircraft, came up with a design for a plane that could meet the current NATO specification for a “Light Tactical Support Fighter”.

The original P.1127 prototype made its first flight in 1960, the RAF ordered a modified version of the P.1127/Kestral in 1966, which became known as the Harrier GR.1.

The Harrier was extensively redeveloped by McDonnell Douglas and British Aerospace, leading to the AV-8B Harrier II and Harrier GR5/GR7/GR9,

The United States Marine Corps makes heavy use of its AV-8B and has developed into a number of sub-variants featuring upgraded systems, software, avionics and structural changes throughout.

While the Harrier is one of the most flexible aircraft ever made, the level of understanding and skill needed to pilot it is considerable.

Thanks to thrust vector and reaction control system, the Harrier is capable of forward flight as well as VTOL and STOL maneuvers; however this requires the skills and understanding associated with helicopters.

The four engine nozzle thrust vectors can be set between zero degrees (horizontal) and 98 degrees (down and slightly forwards), this allows the aircraft to take off and land vertically.

Despite the difficulties in piloting the aircraft, the AV-8B is a capable fighter armed with cannons and several varieties of air-to-air missiles. The AV-8B also doubles as great strike support, able to carry a large amount of stores on its six underwing hardpoints.

The Harrier AV-8B II is used currently by three nations; US, Spain and Italy. Briton’s RAF and Navy, also use its version of the Harrier II.

Specifications

- Engine 1 Rolls-Royce F402-RR-408

- Range 1,000 km

- Weight 10,410 kg

- Top speed 1,000 km/h

- Dimensions Length: 14.11 m, Height: 3.6 m, Wingspan, 9.24 m

Rank 8 – Mitsubishi Zero-Sen (A6M2) Year 1937

The Mitsubishi A6M2 Zero-Sen, a single-seat monoplane fighter conceived as a replacement for the Mitsubishi A5M, was the most famous Japanese plane of World War Two.Manufactured by Mitsubishi Jukogyo & Nakajima, It was the first shipboard fighter capable of surpassing land-based aircraft was famous for its ability to outmaneuver other aircraft such as the

Brewster F2A Buffaloes, Curtiss P-40s and Grumman F4F Wildcats.

Because of the A6Ms exceptional range and performance, it was used in almost every military engagement in the Pacific, until the end of the war.

The Zero- Sen was armed with two 20-mm type 99 cannon, two 7.7mm type 97 machine guns, and possessed the incredible range of 1930 miles using a centerline drop tank.

The unveiling of the A6M2 came as a complete surprise to US forces even though Claire Chennault, the author of ‘The Role of Defensive Pursuit,’ and leader of the Flying Tigers had warned the USAAF about the dangers of Japanese air power.

Once the effectiveness and maneuverability became clear, Chennault was said to have constantly reminded his pilots, ‘Never try to turn with a Zero. Always get above the enemy and try to hit him with the first pass.’

It was only when US Navy PBY Catalina retrieved an almost perfectly intact A6M2, shot down during Pearl Harbor, were the short comings of the aircraft discovered.

The main failing of the A6M2, 3, and 5 fighter aircraft were the lack of armor for the pilot and its fuel tanks were not self sealing and once breached the aircraft was lost.

The consequent testing and of this unmatchable aircraft lead the American aircraft manufacturer Grumman, to lighten the Grumman F4F Wildcat, and install a larger engine on the Grumman F6F Hellcat.

An up until the introduction of the P-38 Lightning, the F6F Hellcat, and the F4U Corsair the A6M Zero remained the premier fighter aircraft in the Pacific.

Specifications

- Engine 1 Nakajima NK1C Sakae 12

- Range 3,107 km

- Weight 1,680 kg

- Top speed 533.5 km/h

- Dimensions Length: 9.06 m, Height: 3.05 m, Wingspan, 12 m

Rank 9 – DR 1 Fokker Triplane Year 1917

The most famous airplane of World War One, Fokker Dr.1 Triplane was designed by Reinhold Platz and built by Fokker-Flugzeugwerke. The DR 1 took its first flight on 5th July 1917 and saw widespread service in the spring of 1918.Many say the aircraft was inspired by Sopwith Triplane however others claim “Reinhold had not even seen the Sopwith before he began designing the DR 1.”

After testing a prototype known as V.3, which suffered from severe wing vibration, Reinhold redesigned the next prototype, the V.4, with hollow struts between the wings. The final design, which came to be known as the DR1, also had improvements to the ailerons and elevators.

The Fokker Dr 1 had one open cockpit, which could hold one pilot and the airframe was made out of steel tubing covered in aircraft doped canvas.

The Dr 1 came equipped with two machine guns which had an intercepting gear that was designed to fire bullets through the propeller arc without hitting the blades.

The DR 1 was a smaller, more maneuverable plane compared to others of World War One; but it was not as fast as most others at that time.

It was in this plane that the most celebrated World War One pilot, Manfred, von Richthofen “The Red Baron”was reported to have made the last of his 80 confirmed victories.

Only 320 Fokker Dr 1’s were made in World War One, so no Fokker Dr 1 is still around today, there are only replicas.

Specifications

- Engine LeRhône type J

- Range 298 km

- Weight 405 kg

- Top speed 185 km/h

- Dimensions Length: 5.77 m, Height: 2.95 m, Wingspan, 7.19 m

Rank 10 – F117 Stealth Fighter Year 1983

The F-117A Nighthawk Stealth Fighter, a single seat, twin engine aircraft developed by Lockheed Martin, was the first aircraft designed to exploit low-observable stealth technology. Development began in 1978 with a contract awarded to Lockheed’s Advanced Development Project know as the “Skunk Works,” in Burbank, Calif.The first flight took place in 1981 but the aircraft remain a Military secret until 1988. The US Air Force had a total of 59 Nighthawks before retirement, starting in 2006 through to 2008, slowly removed the aircraft from the skies (read our previous post on the Retirement of The F-117 Nighthawk).

Also known as the Frisbee and the Wobblin’ Goblin, the Nighthawk, only used in night-time missions (hence the name), is unstable in flight but also highly maneuverable and almost invisible to radar.

The aircraft, powered by two low-bypass F404-GE-F1D2 turbofan engines from General Electric, is mainly constructed of aluminum, areas of the engine and exhaust systems consist of titanium.

The surfaces and edge profiles are optimized to reflect hostile radar into narrow beam signals, directed away from the enemy radar detector. All the doors and opening panels on the aircraft have saw-toothed forward and trailing edges to reflect radar.

Almost all the outer surface is coated with a Radar-Absorbent Material (RAM), even the rectangular air intakes on both sides of the fuselage are covered by gratings coated with RAM.

The aircraft does not rely on radar for navigation or targeting, instead the aircraft is equipped with Forward-Looking Infrared (FLIR) and a Downward-Looking Infrared (DLIR) with laser designator, supplied by Raytheon.

The fly-by-wire is supplied by BAE Systems Aircraft Controls. This system replaces manual control of the single seat aircraft, which is resumed by the pilot for weapon delivery.

The aircraft can carry a range of tactical fighter ordnance including; BLU-109B low-level laser-guided bomb, GBU-10 and GBU-27 laser-guided bomb units, Raytheon AGM-65 Maverick and Raytheon AGM-88 HARM air-to-surface missiles.

The F-117 Nighthawk has been in operational service in many missions including; Operation Just Cause, in Panama; during Operation Desert Storm, in Kosovo; in Afghanistan and during Operation Iraqi Freedom.

F-117’s are now being replaced in the USAF by the more effective F-22 Raptor and F-35 Lighting II.

Specifications

- Engines 2 x General Electric F404-GE-F1D1 Turbofans

- Range approx. 1,110 km

- Weight 13,400 kg

- Top speed approx. 1,040 km/h Dimensions

- Length: 20.08 m, Height: 3.78 m, Wingspan: 13.20 m

Top Ten Fighter Planes - Rank 1 to 5

Rank 1 – P51 Mustang Year 1941

The North American Aviation P-51 Mustang was a long-range single-seat fighter aircraft that entered service with Allied air forces in the middle years of World War II serving as a bomber escort in raids over Germany.

The Mustang was a fast, well-made, and highly durable aircraft; it was also very economical to produce.

The P-51s first flight took place 26th October 1940. It was powered by the Packard V-1650-7, a two-stage two-speed supercharged 12-cylinder Packard-built version of the legendary Rolls-Royce Merlin engine, and was armed with six .50 caliber (12.7 mm) Browning M2/AN machine guns, a version of the Browning adapted for use in combat aircraft.

The first production contract was awarded by the British for 320 NA-73 fighters, named Mustang I by the British and designated the XP-51 by the US Air Force.

The Mustang I made its debut in combat on 10 May 1942 for the British RAF. With its long range and excellent low-level performance, it was employed for tactical reconnaissance and ground-attack duties over the English Channel.

The original aircraft had limitations when flying over 15,000 ft and did not become a valued fighter until modifications were made.

To enhance altitude capabilities, the British tested the Rolls-Royce Merlin engine in the P-51 airframe.

Four airframes were adapted in England to take the Merlin engine. These four planes known as Mustang Xs had deep intakes below the engine for carburetor air. The results of the British tests were passed on to North American.

At the same time on the other side of the Atlantic, North American had undertaken a similar conversion project and was building two Packard Merlin-powered Mustangs.

These improvements increase speed by 51 mph. The newly fitted Packard-built Merlin V-1650-7 was capable of delivering 1,695 hp which provided a speed of 437 mph at 25,000 feet.

The airframes were strengthened to accommodate the extra power, the ventral radiator was deepened, and the carburetor intake was moved from above the nose to below, to accommodate the Merlin updraft induction system.

The P-51 became one of the aviation world’s elite. The total number of 14,819 Mustangs of all types were built for the Army. American Mustangs destroyed 4,950 enemy aircraft in Europe to make them the highest scoring US fighter in the theater.

They were used as dive-bombers, bomber escorts, ground-attackers, interceptors, for photo-recon missions, trainers, transports (with a jump-seat), and after the war, high performance racers.

The Spitfire was originally designed by R. J. Mitchell, chief designer at the Supermarine Aviation Works, a subsidiary of Vickers-Armstrongs. He continued to refine the design until his death from cancer in 1937, whereupon his colleague Joseph Smith became chief designer.

R. J. Mitchell’s 1931 design to meet Air Ministry specification F7/30 for a new and modern fighter capable of 250 mph, the Supermarine Type 224, resulted in an open-cockpit monoplane with bulky gull-wings and a large fixed, spatted undercarriage powered by the 600 horsepower evaporative-cooled Rolls-Royce Goshawk engine.

Based on Reginald Mitchell’s aesthetically pleasing F.7/30 design, the Spitfire was a complex design for its day, with a light alloy monocoque fuselage and a single spar wing, with stressed-skin covering and fabric-covered control surfaces.

The first prototypes employed a DeHavilland two-blade wooden fixed-pitch propeller. After initial testing, this was replaced by a DeHavilland three-blade, two position propeller, and later in 1940, a DeHavilland three-blade constant-speed propeller was substituted.

Production Spitfires had a fixed tail wheel, and triple ejector exhaust manifolds. The PV.12 engine which became the X80 HP Rolls-Royce Merlin II and later the Merlin III engine were installed.

Standard armament in what was known as the “A wing” was eight 0.303-in. Browning machine-guns with 300 rounds of ammunition. The speed of the Spitfire I was marginally higher than that of its principal opponent the Luftwaffe’s Messerschmitt Bf 109E, and it was infinitely more maneuverable than the German fighter, although the Bf 109E could out climb and out dive the British fighter, and its shell-firing cannon had a longer range than the Spitfire’s machine-guns.

In an effort to develop the Spitfire further, two principal modifications were made, these included the introduction of a pressurized cabin and the use of an engine suitably rated for higher altitude. These changes were incorporated in the Spitfire Mark IV.

Deliveries of production Spitfire I’s began in June 1938; just over two years after ‘Mutt’ summers flew the prototype at Southampton on the 5th of March, 1936.

In the two years preceding production, Supermarine laid out their Wollaston factory for large-scale production, and organized one of the largest subcontract schemes ever envisioned in Britain.

Its elliptical wing had a thin cross-section, allowing a higher top speed than the Hawker Hurricane and many other contemporary designs.

Much loved by its pilots, the Spitfire saw service throughout the whole of the Second World War, continuing to serve as a front line fighter for several air forces well into the 1950s.

The Spitfire will always be compared to its main adversary, the Messerschmitt Bf 109: both were among the finest fighters of their day and followed similar design philosophies of marrying a small, streamlined airframe to a powerful liquid-cooled inline engine.

The MiG-21F, a continuation of Soviet jet fighters MiG-15, 17 and 19, is a short-range day fighter-interceptor and the first major production version of the popular MiG-21 series. It is one of around 15 versions of this aircraft that have served in the air arms of many nations around the world.

The E-5 prototype of the MiG-21 was first flown in 1955 and made its first public appearance during the Soviet Aviation Day display at Moscow’s Tushino Airport in June 1956.

When the MiG-21 was first introduced, it exhibited several flaws. Its early version air-to-air missiles, the Vympel K-13 (AA-2 ‘Atoll’), were not successful in combat, and its gyro gunsight was easily thrown off in high-speed maneuvers. Once these problems had been revised, the MiG-21 became a formidable fighter aircraft.

Employing a delta configuration, the MiG-21 was the first successful Soviet aircraft combining fighter and interceptor characteristics in a single aircraft. It was a lightweight fighter, achieving Mach 2 with a relatively low-powered afterburning turbojet.

The fighter holds a number of aviation records, including the most produced supersonic jet aircraft in aviation history, the most produced combat aircraft since World War II, and the longest production run of a combat aircraft.

Its Mach 2 capability exceeds the top speed of many later modern fighter types. It has been estimated that more than 10,000 MiG-21s were built. More than 50 countries of the world have flown the MiG-21.

The Super Hornet was first ordered by the U.S. Navy in 1992. The Super Hornet first flew on November 29, 1995 and initial production on the F/A-18E/F began in 1995. Flight testing started in 1996 with the F/A-18E/F’s first carrier landing in 1997. It later entered service with the United States Navy in 1999, replacing the F-14 Tomcat.

Sharing some similarities as previous Hornet variants, the Navy retained the F/A-18 designation to help sell the program to Congress as a low-risk “derivative”; however the Super Hornet is largely a new aircraft.

Design features that were kept included the avionics, ejection seats, radar, armament, mission computer software, and maintenance/operating procedures.

The F/A-18E/F aircraft are 4.2 feet longer than earlier Hornets, have a 25% larger wing area, and carry 33% more internal fuel which will effectively increase mission range by 41% and endurance by 50%.

The Super Hornet also incorporates two additional weapon stations. This allows for increased payload flexibility by mixing and matching air-to-air and/or air-to-ground ordnance. The aircraft can also carry the complete complement of “smart” weapons, including the newest joint weapons such as JDAM and JSOW.

The Super Hornet can carry approximately 17,750 pounds (8,032 kg) of external load on eleven stations. It has an all-weather air-to-air radar and a control system for accurate delivery of conventional or guided weapons.

There are two wing tip stations, four inboard wing stations for fuel tanks or air-to-ground weapons, two nacelle fuselage stations for Sparrows or sensor pods, and one centerline station for fuel or air-to-ground weapons. An internal 20 mm M61A1 Vulcan cannon is mounted in the nose.

Survivability is an important feature of the Super Hornet design. The US Navy took a “balanced approach” to survivability in its design. This means that it does not rely on low-observable technology, such as stealth systems, to the exclusion of other survivability factors. Instead, its design incorporates a combination of stealth, advanced electronic-warfare capabilities, reduced ballistic vulnerability, the use of standoff weapons, and innovative tactics that cumulatively and collectively enhance the safety of the fighter and crew.

The Super Hornet, unlike the previous Hornet, can be equipped with an aerial refueling system (ARS) or “buddy store” for the refueling of other aircraft.

In 2003, the Navy identified a flaw in the Super Hornet’s under wing pylons, which could reduce the aircraft’s service life unless repaired. The problem has been corrected on new airplanes and existing airplanes will be repaired starting in 2009.

The versatility of the F-18 Super Hornet has led the aircraft to be used in such missions including; day/night strikes with precision-guided weapons, anti-air warfare, fighter escort, close air support, suppression of enemy air defense, maritime strikes, reconnaissance, forward air control (Airborne) (FAC(A)), air-to-air refueling as well as leaflet drops with payload delivery unit 5 (PDU-5) containers.

The company was renamed Messerschmitt AG in July 1938 when Erhard Milch finally allowed Willy Messerschmitt to acquire the company; from then on, all Messerschmitt aircraft were to carry the “Me” designation except those already assigned a Bf prefix.

Perhaps not the best performer of the war, even its pilots would admit that it was not the safest or most comfortable plane to fly. But its combat record, from beginning to end, was monumental, and it was the weapon of choice for the greatest fighter pilots in history.

A total of 33,984 units were produced up to April 1945. Accounting for 47% of all German aircraft production, as well as 57% of all German fighter types produced.

The ME 109 became the backbone of the Luftwaffe fighter force in World War II, although it began to be partially replaced by the Focke-Wulf Fw 190 from 1941.

The ME/Bf 109 was the most successful fighter of World War II, shooting down more aircraft than any of its contemporaries. It was flown by the three top-scoring fighter aces of World War II: Erich Hartmann, the top scoring fighter pilot of all time with 352 victories, Gerhard Barkhorn with 301 victories, and Günther Rall with 275 victories. All of them flew with Jagdgeschwader 52, a unit which exclusively flew the Bf 109 and was credited with over 10,000 victories.

Originally conceived as an interceptor, it was later developed to fulfill multiple tasks, serving as bomber escort, fighter bomber, day-, night- all-weather fighter, bomber destroyer, ground-attack aircraft, and as reconnaissance aircraft.

The ME 109, including such features as an all-metal monocoque construction, a closed canopy, and retractable landing gear, was one of the first true modern fighters of the era.

Although the Bf 109 had weaknesses, including short range and challenging take off and landing characteristics, it stayed competitive with Allied fighter aircraft until the end of the war.

The North American Aviation P-51 Mustang was a long-range single-seat fighter aircraft that entered service with Allied air forces in the middle years of World War II serving as a bomber escort in raids over Germany.

The Mustang was a fast, well-made, and highly durable aircraft; it was also very economical to produce.

The P-51s first flight took place 26th October 1940. It was powered by the Packard V-1650-7, a two-stage two-speed supercharged 12-cylinder Packard-built version of the legendary Rolls-Royce Merlin engine, and was armed with six .50 caliber (12.7 mm) Browning M2/AN machine guns, a version of the Browning adapted for use in combat aircraft.

The first production contract was awarded by the British for 320 NA-73 fighters, named Mustang I by the British and designated the XP-51 by the US Air Force.

The Mustang I made its debut in combat on 10 May 1942 for the British RAF. With its long range and excellent low-level performance, it was employed for tactical reconnaissance and ground-attack duties over the English Channel.

The original aircraft had limitations when flying over 15,000 ft and did not become a valued fighter until modifications were made.

To enhance altitude capabilities, the British tested the Rolls-Royce Merlin engine in the P-51 airframe.

Four airframes were adapted in England to take the Merlin engine. These four planes known as Mustang Xs had deep intakes below the engine for carburetor air. The results of the British tests were passed on to North American.

At the same time on the other side of the Atlantic, North American had undertaken a similar conversion project and was building two Packard Merlin-powered Mustangs.

These improvements increase speed by 51 mph. The newly fitted Packard-built Merlin V-1650-7 was capable of delivering 1,695 hp which provided a speed of 437 mph at 25,000 feet.

The airframes were strengthened to accommodate the extra power, the ventral radiator was deepened, and the carburetor intake was moved from above the nose to below, to accommodate the Merlin updraft induction system.

The P-51 became one of the aviation world’s elite. The total number of 14,819 Mustangs of all types were built for the Army. American Mustangs destroyed 4,950 enemy aircraft in Europe to make them the highest scoring US fighter in the theater.

They were used as dive-bombers, bomber escorts, ground-attackers, interceptors, for photo-recon missions, trainers, transports (with a jump-seat), and after the war, high performance racers.

Rank 2 – Supermarine Spitfire Year 1938

The Supermarine Spitfire was a British single-seat fighter aircraft, used by the Royal Air Force and many other Allied countries during the Second World War, and into the 1950s. The extremely adaptable deign of the Spitfire led to 24 marks of aircraft and many sub-variants within the marks.The Spitfire was originally designed by R. J. Mitchell, chief designer at the Supermarine Aviation Works, a subsidiary of Vickers-Armstrongs. He continued to refine the design until his death from cancer in 1937, whereupon his colleague Joseph Smith became chief designer.

R. J. Mitchell’s 1931 design to meet Air Ministry specification F7/30 for a new and modern fighter capable of 250 mph, the Supermarine Type 224, resulted in an open-cockpit monoplane with bulky gull-wings and a large fixed, spatted undercarriage powered by the 600 horsepower evaporative-cooled Rolls-Royce Goshawk engine.

Based on Reginald Mitchell’s aesthetically pleasing F.7/30 design, the Spitfire was a complex design for its day, with a light alloy monocoque fuselage and a single spar wing, with stressed-skin covering and fabric-covered control surfaces.

The first prototypes employed a DeHavilland two-blade wooden fixed-pitch propeller. After initial testing, this was replaced by a DeHavilland three-blade, two position propeller, and later in 1940, a DeHavilland three-blade constant-speed propeller was substituted.

Production Spitfires had a fixed tail wheel, and triple ejector exhaust manifolds. The PV.12 engine which became the X80 HP Rolls-Royce Merlin II and later the Merlin III engine were installed.

Standard armament in what was known as the “A wing” was eight 0.303-in. Browning machine-guns with 300 rounds of ammunition. The speed of the Spitfire I was marginally higher than that of its principal opponent the Luftwaffe’s Messerschmitt Bf 109E, and it was infinitely more maneuverable than the German fighter, although the Bf 109E could out climb and out dive the British fighter, and its shell-firing cannon had a longer range than the Spitfire’s machine-guns.

In an effort to develop the Spitfire further, two principal modifications were made, these included the introduction of a pressurized cabin and the use of an engine suitably rated for higher altitude. These changes were incorporated in the Spitfire Mark IV.

Deliveries of production Spitfire I’s began in June 1938; just over two years after ‘Mutt’ summers flew the prototype at Southampton on the 5th of March, 1936.

In the two years preceding production, Supermarine laid out their Wollaston factory for large-scale production, and organized one of the largest subcontract schemes ever envisioned in Britain.

Its elliptical wing had a thin cross-section, allowing a higher top speed than the Hawker Hurricane and many other contemporary designs.

Much loved by its pilots, the Spitfire saw service throughout the whole of the Second World War, continuing to serve as a front line fighter for several air forces well into the 1950s.

The Spitfire will always be compared to its main adversary, the Messerschmitt Bf 109: both were among the finest fighters of their day and followed similar design philosophies of marrying a small, streamlined airframe to a powerful liquid-cooled inline engine.

Specifications

- Engine 1 Rolls Royce Merlin 45

- Range 580 km

- Weight 3,300 kg

- Top speed 520 km/h

- Dimensions Length: 10.77 m, Height: 3.90 m, Wingspan, 11.23 m

Rank 3 – MIG 21 (F-13 / Fishbed C) Year 1959

The Mikoyan-Gurevich MiG-21 (“Fishbed”) is a supersonic jet fighter aircraft, designed and built by the Mikoyan-Gurevich Design Bureau in the Soviet Union.

The MiG-21F, a continuation of Soviet jet fighters MiG-15, 17 and 19, is a short-range day fighter-interceptor and the first major production version of the popular MiG-21 series. It is one of around 15 versions of this aircraft that have served in the air arms of many nations around the world.

The E-5 prototype of the MiG-21 was first flown in 1955 and made its first public appearance during the Soviet Aviation Day display at Moscow’s Tushino Airport in June 1956.

When the MiG-21 was first introduced, it exhibited several flaws. Its early version air-to-air missiles, the Vympel K-13 (AA-2 ‘Atoll’), were not successful in combat, and its gyro gunsight was easily thrown off in high-speed maneuvers. Once these problems had been revised, the MiG-21 became a formidable fighter aircraft.

Employing a delta configuration, the MiG-21 was the first successful Soviet aircraft combining fighter and interceptor characteristics in a single aircraft. It was a lightweight fighter, achieving Mach 2 with a relatively low-powered afterburning turbojet.

The fighter holds a number of aviation records, including the most produced supersonic jet aircraft in aviation history, the most produced combat aircraft since World War II, and the longest production run of a combat aircraft.

Its Mach 2 capability exceeds the top speed of many later modern fighter types. It has been estimated that more than 10,000 MiG-21s were built. More than 50 countries of the world have flown the MiG-21.

Specifications

- Engine 1 Tumanski R-11F-300 jet

- Range 1,640 km

- Weight 4,600 kg

- Top speed 2,093 km/h

- Dimensions Length: 15.77 m, Height: 7.16 m, Wingspan, 4.80 m

Rank 4 – F 18 Super Hornet Year 1983

The Boeing F/A-18E/F Super Hornet is a supersonic carrier-capable fighter/attack aircraft. It is a larger and more advanced derivative of the F/A-18C/D Hornet.The Super Hornet was first ordered by the U.S. Navy in 1992. The Super Hornet first flew on November 29, 1995 and initial production on the F/A-18E/F began in 1995. Flight testing started in 1996 with the F/A-18E/F’s first carrier landing in 1997. It later entered service with the United States Navy in 1999, replacing the F-14 Tomcat.

Sharing some similarities as previous Hornet variants, the Navy retained the F/A-18 designation to help sell the program to Congress as a low-risk “derivative”; however the Super Hornet is largely a new aircraft.

Design features that were kept included the avionics, ejection seats, radar, armament, mission computer software, and maintenance/operating procedures.

The F/A-18E/F aircraft are 4.2 feet longer than earlier Hornets, have a 25% larger wing area, and carry 33% more internal fuel which will effectively increase mission range by 41% and endurance by 50%.

The Super Hornet also incorporates two additional weapon stations. This allows for increased payload flexibility by mixing and matching air-to-air and/or air-to-ground ordnance. The aircraft can also carry the complete complement of “smart” weapons, including the newest joint weapons such as JDAM and JSOW.

The Super Hornet can carry approximately 17,750 pounds (8,032 kg) of external load on eleven stations. It has an all-weather air-to-air radar and a control system for accurate delivery of conventional or guided weapons.

There are two wing tip stations, four inboard wing stations for fuel tanks or air-to-ground weapons, two nacelle fuselage stations for Sparrows or sensor pods, and one centerline station for fuel or air-to-ground weapons. An internal 20 mm M61A1 Vulcan cannon is mounted in the nose.

Survivability is an important feature of the Super Hornet design. The US Navy took a “balanced approach” to survivability in its design. This means that it does not rely on low-observable technology, such as stealth systems, to the exclusion of other survivability factors. Instead, its design incorporates a combination of stealth, advanced electronic-warfare capabilities, reduced ballistic vulnerability, the use of standoff weapons, and innovative tactics that cumulatively and collectively enhance the safety of the fighter and crew.

The Super Hornet, unlike the previous Hornet, can be equipped with an aerial refueling system (ARS) or “buddy store” for the refueling of other aircraft.

In 2003, the Navy identified a flaw in the Super Hornet’s under wing pylons, which could reduce the aircraft’s service life unless repaired. The problem has been corrected on new airplanes and existing airplanes will be repaired starting in 2009.

The versatility of the F-18 Super Hornet has led the aircraft to be used in such missions including; day/night strikes with precision-guided weapons, anti-air warfare, fighter escort, close air support, suppression of enemy air defense, maritime strikes, reconnaissance, forward air control (Airborne) (FAC(A)), air-to-air refueling as well as leaflet drops with payload delivery unit 5 (PDU-5) containers.

Specifications

- Engines 2 F414-GE-400 turbofans

- Range 2,453 km

- Weight 29,932 kg (max.)

- Top speed 2,145 km/h

- Dimensions Length: 18.5 m, Height: 4.87 m, Wingspan, 13.68 m

Rank 5 – Messerschmidt ME109 Year 1937

Messerschmidt ME109 was the official Reichsluftfahrtministerium (German Aviation Ministry, RLM) designation, the design was submitted by the Bayerische Flugzeugwerke company, and was used exclusively in all official German documents dealing with this aircraft family.The company was renamed Messerschmitt AG in July 1938 when Erhard Milch finally allowed Willy Messerschmitt to acquire the company; from then on, all Messerschmitt aircraft were to carry the “Me” designation except those already assigned a Bf prefix.

Perhaps not the best performer of the war, even its pilots would admit that it was not the safest or most comfortable plane to fly. But its combat record, from beginning to end, was monumental, and it was the weapon of choice for the greatest fighter pilots in history.

A total of 33,984 units were produced up to April 1945. Accounting for 47% of all German aircraft production, as well as 57% of all German fighter types produced.

The ME 109 became the backbone of the Luftwaffe fighter force in World War II, although it began to be partially replaced by the Focke-Wulf Fw 190 from 1941.

The ME/Bf 109 was the most successful fighter of World War II, shooting down more aircraft than any of its contemporaries. It was flown by the three top-scoring fighter aces of World War II: Erich Hartmann, the top scoring fighter pilot of all time with 352 victories, Gerhard Barkhorn with 301 victories, and Günther Rall with 275 victories. All of them flew with Jagdgeschwader 52, a unit which exclusively flew the Bf 109 and was credited with over 10,000 victories.

Originally conceived as an interceptor, it was later developed to fulfill multiple tasks, serving as bomber escort, fighter bomber, day-, night- all-weather fighter, bomber destroyer, ground-attack aircraft, and as reconnaissance aircraft.

The ME 109, including such features as an all-metal monocoque construction, a closed canopy, and retractable landing gear, was one of the first true modern fighters of the era.

Although the Bf 109 had weaknesses, including short range and challenging take off and landing characteristics, it stayed competitive with Allied fighter aircraft until the end of the war.

Specifications

- Engine Daimler-Benz DB 605A

- Range 550 km

- Weight 2,600 kg

- Top speed 635 km/h

- Dimensions Length: 8.94 m, Height: 2.59 m, Wingspan, 9.92 m

Subscribe to:

Posts (Atom)